TNO Automotive

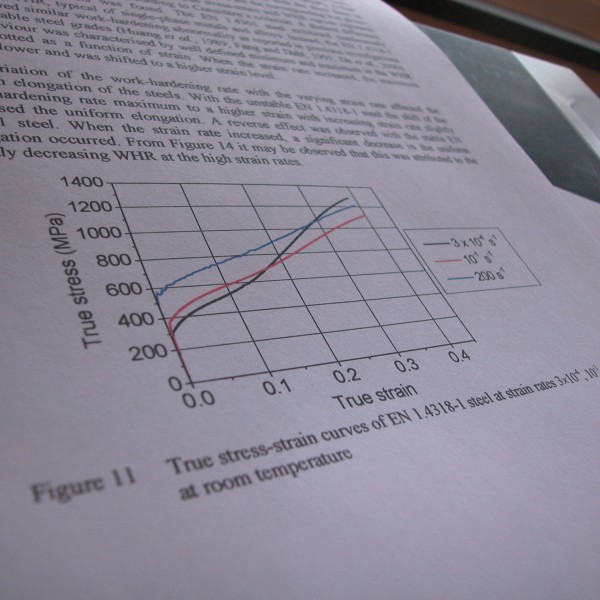

A variety of stainless and regular steels have been tested in several projects at a range of strain rates in order to investigate the resistance of the materials at crash loads. These crash loads occur during accidents such as car crash. Considerable straining has been measured even at high strain rates and an elevated material strength.

Ref:

JUHO TALONEN, PERTTI NENONEN, GERSOM PAPE, and HANNU HÄNNINEN, Effect of Strain Rate on the Strain-Induced ‘-Martensite Transformation and Mechanical Properties of Austenitic Stainless Steels, METALLURGICAL AND MATERIALS TRANSACTIONS A, VOLUME 36A, FEBRUARY 2005-421

Ref:

Juho Talonen, EFFECT OF STRAIN-INDUCED a’-MARTENSITE TRANSFORMATION ON MECHANICAL PROPERTIES OF METASTABLE AUSTENITIC STAINLESS STEELS, Dissertations 71, Espoo 2007, Doctoral Dissertation, Helsinki University of Technology, Department of Mechanical Engineering, Laboratory of Engineering Materials, 2007

Rechts