TNO – BASF Ludwigshafen

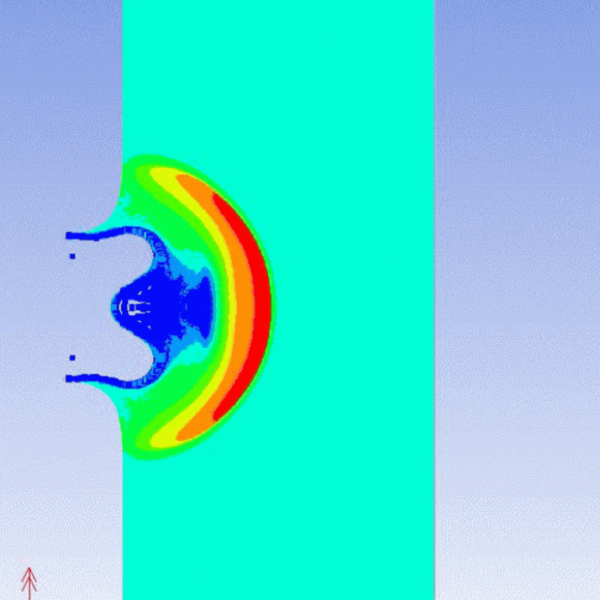

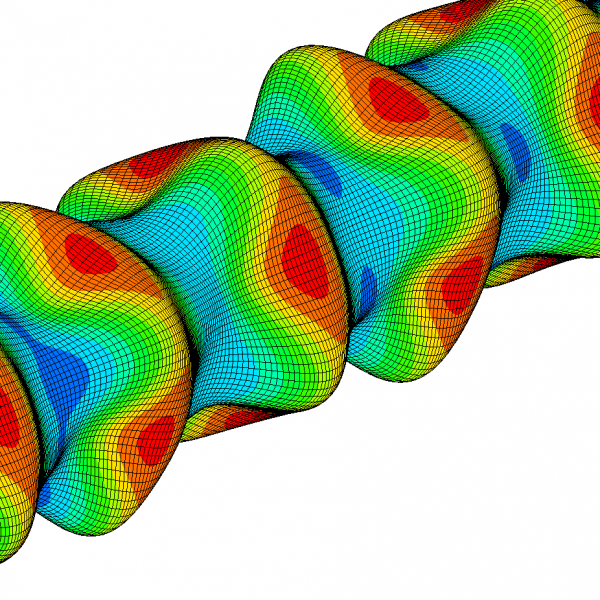

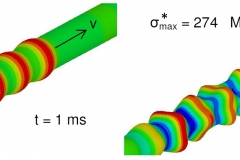

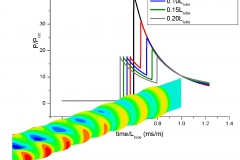

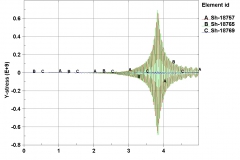

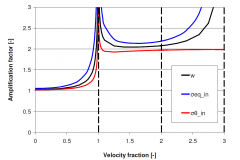

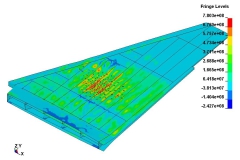

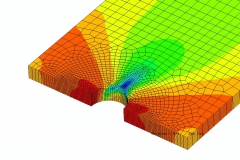

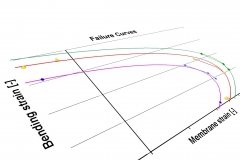

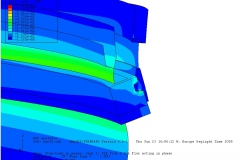

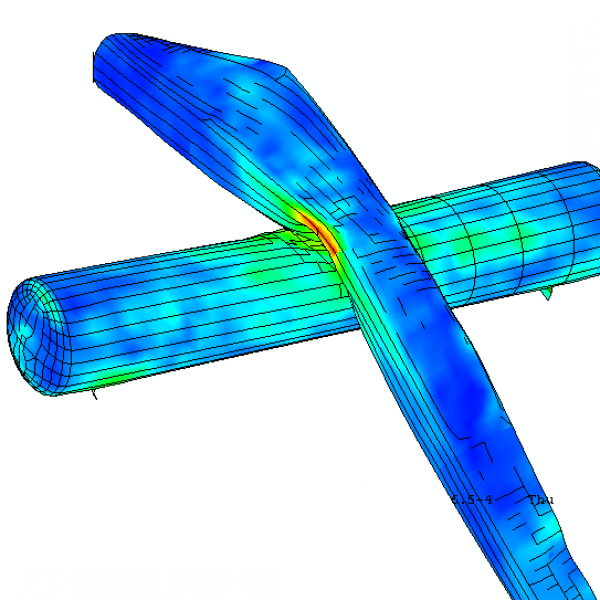

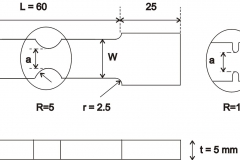

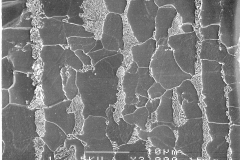

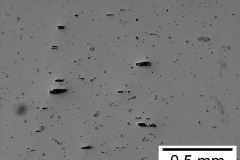

The mechanical response of process piping loaded by an internal moving gas detonation has been investigated by DTRL, supporting the TNO Flow and Structural Dynamics section in a research project with BASF Ludwigshafen. Combined analytical and numerical methods have been explored in order to gain insight in the dynamic pipe response at high strain rate loading and elastic-plastic deformation. Special attention has been paid to the influence of:

- Detonation (critical) velocity

- Material properties

- Limited plasticity and strain rate effects

- Pipe bends, dead ends & T-sections

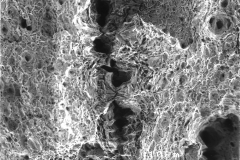

- Pipe corrosion & assymetric loading

- Detonation decay time

- Mode coupling

- Reflected flexural waves

Used Methods/Software:

- Matcad / Maple / LS-Dyna

- Analytical & numerical modelling

- Comparison with experiments

Results have been published in:

J.P.M. Smeulers, G. Pape, Design Rules for Pipe Systems Subject to Internal Explosions, PVP2010-25695 (Part 1) & PVP2010-26177 (Part 2), Proceedings of the 2010 Pressure Vessel & Piping Conference, Bellevue, Washington.

J.P.M. Smeulers, G. Pape, N.E. Ligterink, Modeling of the Effect of Plasticity on the Response of Pipe Systems to Internal Explosions, PVP2012-78482, Proceedings of the 2012 Pressure Vessels & Piping Conference, Toronto, Canada.

H.P. Schildberg, J.P.M. Smeulers, G. Pape, Experimental Determination of the Static Equivalent Pressures of Gas Phase Detonations in Pipes and Comparison with Numerical Models, PVP2013-97677, Proceedings of the 2013 Pressure Vessels & Piping Conference, Paris, France.